Thursday, 29 September 2011

Tuesday, 20 September 2011

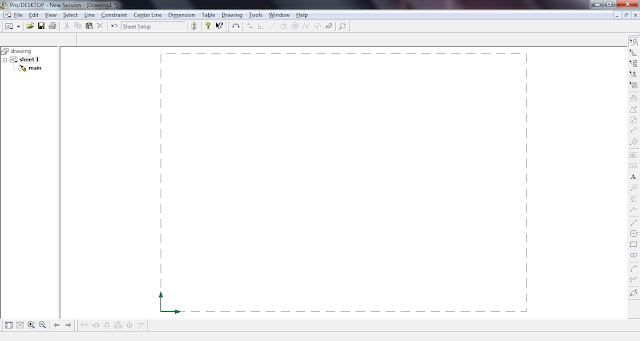

Pro-Desktop (Converting Diagram Into DXF File)

1. Create design and save (Do Not Close Window)

2. Create new engineering drawing (File / Engineering Drawing)

3. Choose template (note - for this tutorial I chose bottom right picture)

3. Remove the box in the bottom right corner by going to Sheet 1 / Sheet Setup (If you chose bottom right picture)

4. This box should appear (select Specify Format and choose ISO - A2)

5. The box has been removed

6. Input your design by going to Drawing / Add Modelling View

7. Select you design and press OK (Note - the chosen design must be open in a different window)

8. Move your design to save material by click and dragging it

9. Save your drawing

10. Export it as a DXF file by choosing File / Export / DXF File

11. Choose where you want to save the dxf file and select correct properties and press OK

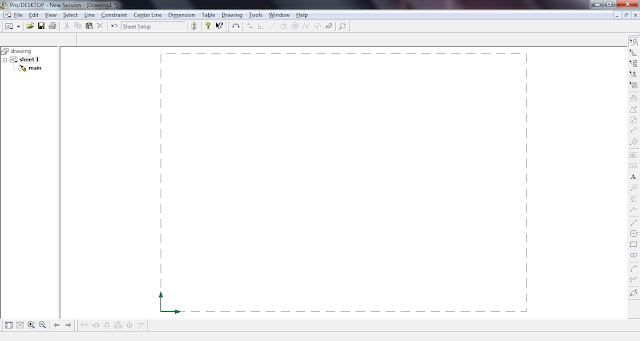

2. Create new engineering drawing (File / Engineering Drawing)

3. Choose template (note - for this tutorial I chose bottom right picture)

3. Remove the box in the bottom right corner by going to Sheet 1 / Sheet Setup (If you chose bottom right picture)

4. This box should appear (select Specify Format and choose ISO - A2)

5. The box has been removed

6. Input your design by going to Drawing / Add Modelling View

7. Select you design and press OK (Note - the chosen design must be open in a different window)

8. Move your design to save material by click and dragging it

9. Save your drawing

10. Export it as a DXF file by choosing File / Export / DXF File

11. Choose where you want to save the dxf file and select correct properties and press OK

Monday, 12 September 2011

Compression Moulding

What is Compression Moulding?

Compression Moulding is a process where molten plastic is compressed to create a shape. The molten plastic then takes the shape of the mould. This is the only process capable of of moulding thermosetting plastics.

Compression Moulding is a process where molten plastic is compressed to create a shape. The molten plastic then takes the shape of the mould. This is the only process capable of of moulding thermosetting plastics.

Injection Moulding

What is Injection Moulding?

Injection Moulding is a process of moulding where the material is injected into the mould to create a product. The material (usually granulated or powdered thermoplastics) is heated so that it becomes a liquid state and then forced under pressure into a mould. The material into the mould cools forming a part / product.

Injection Moulding is a process of moulding where the material is injected into the mould to create a product. The material (usually granulated or powdered thermoplastics) is heated so that it becomes a liquid state and then forced under pressure into a mould. The material into the mould cools forming a part / product.

click for animation

Rotational Moulding

What is Rotational Moulding?

Rotational moulding is a process in which hollow parts/products are manufactured. The most common material used is plastic to create products such as plastic balls. The material is heated up so that it becomes a liquid state. It is then rotated, once the liquid has taken the shape of the mould water or air is used to cool the material. The material then becomes a solid state. The mould is then broken apart to reveal the product.

Rotational moulding is a process in which hollow parts/products are manufactured. The most common material used is plastic to create products such as plastic balls. The material is heated up so that it becomes a liquid state. It is then rotated, once the liquid has taken the shape of the mould water or air is used to cool the material. The material then becomes a solid state. The mould is then broken apart to reveal the product.

Thursday, 8 September 2011

Polymers (Thermoplastic Products Characteristics)

WORK IN PROGRESS - WILL BE FINISHED BY END OF WEEK

Polymers (Thermosetting Products Characteristics)

WORK IN PROGRESS - WILL BE FINISHED BY END OF WEEK

Polymers (Thermosetting Plastics)

Here are the types of Thermosetting Plastics:

- Epoxy Resins

- Melamine Formaldehyde

- Polyester Resins

- Urea Formaldehyde

Polymers (General Characteristics of Plastics)

Here are some general characteristics of plastics:

- Good electrical and thermal insulators

- Good strength to weight ratio

- Good resistance to atmospheric and chemical erosion

- Low melting point

- Lightweight

- Wide range of colours (due to pigments) and transparency

- Main categories are Thermosetting and Thermoplastic

Products Made From Polymers

Here are some examples of some products made from Polymers:

Hardhat - ABS

Bucket - HDPE

Tubaware Boxes - PP

Outside Garden Lights - PMMA

Polystyrene Cup - PS

Gear Mechanism - NYLON

Wiring - PVC

Lab Glasses - PC

Washing Liquid Bottle - LDPE

Plastic Windows- uPVC

Plastic Coating For Cutlery - CA

Polymers (Thermoplastics)

Here are some Thermoplastics:

ABS - Acrylonitrile Butadiene Stryrene

CA - Cellulose Acetate

NYLON - Polyamide

PMMA - PolyMethylMethAcrylate (Acrylic)

PP - Polypropylene

HIPS - High Impact Polystrene

PS - Polystyrene

LDPE - Low Density Polyehthlene

HDPE - High Density Polyethlene

uPVC - Polyvynil Chloride

PVC - (Unplasticised Flexible) Polyvynil Chloride

PET - Poly Ethylene Terephtalate

PC - Polycarbonate

ABS - Acrylonitrile Butadiene Stryrene

CA - Cellulose Acetate

NYLON - Polyamide

PMMA - PolyMethylMethAcrylate (Acrylic)

PP - Polypropylene

HIPS - High Impact Polystrene

PS - Polystyrene

LDPE - Low Density Polyehthlene

HDPE - High Density Polyethlene

uPVC - Polyvynil Chloride

PVC - (Unplasticised Flexible) Polyvynil Chloride

PET - Poly Ethylene Terephtalate

PC - Polycarbonate

Thermosetting and Thermoplastics

There are two main types of polymers (Plastics) - Thermosetting and Thermoplastic.

Thermoplastic:

Thermoplastic:

- Thermoplastics soften when heated, once heated they can be moulded into any shape. After cooling down they harden. The main benieft of thermoplastics is that once moulded they can be reshaped.

Thermosetting:

- Thermosetting plastics soften when heated, once heated they can be moulded into any shape. After cooling down they harden. The main disadvantage is that once moulded they can't be reshaped.

Tuesday, 6 September 2011

Assignment One - I Should Never Of Purchased

A while back from now I purchased a brand new 32inch LED Samsung TV, at a cost of over £100, which was extremely thin and had a clear edges round the sides. Its function wasn't designed fully as within three days the TV decided to break whilst it was turned on. One moment it was working the next it was broken. Although the light that projects a green light when turned on was still on the actual screen was black.

The form of the TV was rectangle and was probably made from ABS as it needs to be durable, have a good strength to weight ratio and it must be non-toxic. The plastic had a shiny black finish.

Before it broke the function was great with built in freeview, an easy to read and understand guide and fantastic quality TV. The freeview was a brilliant extra as a few months before my area changed from Analogue to Digital so it meant we didn't have to buy a digital box

The fact that it was LED meant that Samsung were able to design it to be thinner that old style TVs.

A possible cause of the fault might be due to heavy usage of a TV by a family of 5 including 1 child and 2 teenagers. However the TV showed no fault in the first two days of use.

Despite the fact it had broken within three days of purchase I decided to claim it on the guarantee and I quickly received a new TV which still works today.

The form of the TV was rectangle and was probably made from ABS as it needs to be durable, have a good strength to weight ratio and it must be non-toxic. The plastic had a shiny black finish.

Before it broke the function was great with built in freeview, an easy to read and understand guide and fantastic quality TV. The freeview was a brilliant extra as a few months before my area changed from Analogue to Digital so it meant we didn't have to buy a digital box

The fact that it was LED meant that Samsung were able to design it to be thinner that old style TVs.

A possible cause of the fault might be due to heavy usage of a TV by a family of 5 including 1 child and 2 teenagers. However the TV showed no fault in the first two days of use.

Despite the fact it had broken within three days of purchase I decided to claim it on the guarantee and I quickly received a new TV which still works today.

Subscribe to:

Comments (Atom)